What is Tensile splitting strength testing of concrete?

Tensile splitting strength testing is an indirect measure evaluating concretes resistance to tensile loading and the materials ability to resist cracking.

As concrete is approximately ten times weaker in tension than compression and tensile loads are extremely common for structural members such as beams or floor slabs, the accurate assessment of tensile strength is vital to ensure sufficient structural stability and load bearing capacity.

How does Tensile splitting strength testing work?

The test works by applying compression to a narrow region along the centre of a cylindrical core using a compressive-testing machine. Force levels are increased until a vertical crack is created along the central axis of the cylinder, splitting the specimen.

What is Tensile splitting strength testing used for?

Deterioration process | Defects | Control of repairs |

Deterioration processes involving bulk concrete. | Internal microcracks Deterioration of interfaces | - |

How do I carry out Tensile splitting strength testing?

The procedure for tensile splitting strength testing of concrete is laid out in BS EN 12390-6.

Test specimens must be cored from existing structures, or, cast in cylindrical moulds and stored in in laboratory conditions as per BS EN 12390-1 and BS EN 12390-2.

Where shapes/dimensions of specimens exceed the respective tolerances of BS EN 12390-1, level uneven surfaces by grinding and correct any deviation of angles by cutting and/or grinding.

Measure the test specimen and calculate the average diameter to the nearest 0.2 mm.

Place the test specimen centrally in the testing machine, optionally using a jig.

Carefully position packing strips and, if required, loading pieces, along the top and bottom of the plane of loading of the specimen (Figure 2).

Select a constant rate of stress within the range 0.04 MPa/s (N/mm²·s) to 0.06 MPa/s (N/mm²·s).

Apply an initial load which must not exceed 20% of the failure load.

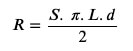

Apply increasing loads to the specimen at a rate determined via Equation 1; until no greater load can be sustained.

where: R = loading rate (N/s), L = specimen length (mm), d = cross section dimension (mm), S = stress rate (N/mm2/s).

Equation 1. Loading rate calculation

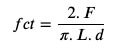

Record the maximum load sustained in N and covert to N/mm2 using Equation 2 to the nearest 0.05 N/mm2 and asses the method of failure.

where: fct = tensile splitting strength (N/mm2), F = max load (N), d = cross section dimension (mm), L = specimen length.

Equation 2. Tensile splitting strength

What equipment and expertise are required for Tensile splitting strength testing?

BS EN 12390-6:2023 stipulates the equipment required to carry out tensile splitting strength testing of concrete specimens.

The test requires a compressive strength test machine that meets BS EN 12390-4:2019 such as those from Impact test or ELE.

If possible, a jig for centring the specimen in the test device should be used. Packing strips for tensile splitting tests should conform to BS EN 316, be hardboard with a density ≥900 kg/m³, width of 15 ± 1 mm, thickness of 4 ± 1 mm, and a length exceeding the specimen's contact line (Figure 4).

What are the advantages of Tensile splitting strength testing?

The test is straightforward, requiring minimal specialized equipment, making it accessible and easy to execute in various settings.

Applies a load that induces uniform tensile stress, minimizing stress concentrations and simplifying interpretation.

Requires fewer resources than direct tensile tests, making it an economical choice for projects.

Suitable for assessing both new and old concrete, including high-performance and fibre-reinforced types, across different construction projects.

Enables comparison between different concrete mixes, informing material selection and mix design optimization.

Results can predict material's durability and performance, aiding in design and construction decisions to prevent cracking issues.

What are the disadvantages of Tensile splitting strength testing?

The test can introduce stress concentration at the points of load application, which might not accurately represent the material's uniform tensile strength.

The results are highly sensitive to the specimen's shape and size. Deviations from the standard dimensions can lead to significant variations in measured strength.

The stress distribution during the test does not perfectly simulate real-world conditions where concrete is subjected to complex stress patterns.

Without proper expertise, the results can be misinterpreted. Understanding the fracture mechanics and the specific failure modes of concrete is crucial for accurate analysis.

The outcomes can be influenced by the surface condition of the specimens. Imperfections or variations in the preparation process can affect the test results.

The tensile splitting strength can be affected by the size and type of aggregates used in the concrete mix, adding another layer of complexity to the interpretation of results.

The test results can be affected by environmental conditions prior to testing, such as moisture content and temperature, necessitating strict control over specimen storage and preparation.

How accurate is Tensile splitting strength testing?

The accuracy of tensile splitting tests in concrete condition assessment depends on factors like specimen geometry, size, packing strip material, and adherence to standardized procedures.

These tests, while simple and effective for determining tensile strength, are subject to variability due to different testing conditions.

Cubic specimens often report tensile strengths about 10% higher than cylindrical ones, with smaller cubes indicating higher strengths than larger ones, highlighting the need for standardized dimensions for comparability.

The use of hardboard packing strips chosen for their ability to minimize result variability, illustrates the influence of configurations on test outcomes, by facilitating lower standard deviations, these strips enhance the reliability of tensile strength measurements.

What are the limits of Tensile splitting strength testing?

In structures with historical or architectural significance, taking cores could compromise structural integrity, aesthetic appeal or historical authenticity.

Structures with embedded systems electrical, plumbing, or mechanical systems, may also be unsuitable for coring without risking damage to these systems.

The process of coring and testing can pose safety risks, especially in deteriorated or hazardous structures. Environmental and safety precautions are necessary to manage hazards associated with coring, including dust control, asbestos protection and structural stability during and after core extraction.

Testing provides information only about the specific locations from which cores are taken, potentially missing variations in materials or conditions across the structure.

Holes left from coring must be repaired ensuring that these areas are as strong and durable as the rest of the structure.

The process of core extraction, testing, and subsequent repairs can be costly and time consuming. In some cases, the financial implications may outweigh the benefits, especially for large-scale or complex structures where extensive sampling is necessary.

The accuracy of the test results heavily relies on the expertise of the personnel conducting the tests. The need for specialized equipment and knowledge can limit the availability of testing, especially in regions or contexts where such resources are scarce.

The condition of the concrete, including moisture content and temperature, can significantly affect test results. Testing specimens that are not representative of the structure's typical state can lead to inaccurate assessments.

The act of coring itself can compromise the structural integrity of the concrete, especially in critical or already weakened areas. This is a significant concern in load-bearing elements or in structures where redundancy and load paths are not well defined.

Ancillary information

Maturity of test: > 10 years

Qualification & interpretation : Specialised lab

Service disruption: No

Preliminary works: Yes

Time consumption Medium (one day)

Cost Medium

Access to element 1 face