What is Non-Steady State Chloride migration coefficient testing?

Non-Steady State Chloride migration is a rapid test method for determining the rate that chlorides can penetrate concrete samples.

Chloride testing aims to establish the level of chlorides that will reach the reinforcement of a concrete structure over time to provide realistic estimations of the corrosion risk and the time until its initiation.

How does Non-Steady State Chloride migration coefficient testing work?

Chloride ingress causes concrete failure by diffusing through the cover layer to reach the steel reinforcement, where it disrupts the protective oxide layer on the steel, initiating corrosion that weakens structural integrity.

Measuring the rate at which these ions move through newly cast concrete or samples cored from an existing structure is therefore vital to assess the durability and lifespan these elements will have, however, in real time, this is an extremely long process.

Non-Steady State Chloride migration coefficient testing works by applying an external electric current to force chloride ions into cylindrical concrete specimens, accelerating the rate of chloride ingress and dramatically reducing the testing time.

The test set up is composed of two reservoirs of catholyte (10% NaCl) and anolyte (0.3M NaOH) solutions that sandwich the specimen. Chlorides are driven from the catholyte to the analyte through the concrete sample; with better quality, more durable concrete providing greater resistance.

After a certain test duration, the specimen is axially split and a silver nitrate solution is sprayed on to one of the freshly split sections. Where chlorides are present, this solution precipitates as buff white deposit.

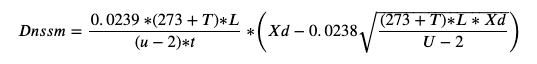

The non-steady-state migration coefficient (x10-12 m2/s) is computed using Equation 1 based on the absolute value of applied voltage, average temperature, and other test factors.

What is Non-Steady State Chloride migration coefficient testing used for?

Deterioration process | Defects | Control of repairs |

Concrete damage | Quality of Concrete replacement for durability |

How do I carry out Non-Steady State Chloride migration coefficient testing?

A step-by-step procedure for non-steady state chloride migration coefficient testing is provided by Nordtest Method NT BUILD 492:

Cylindrical cores with a diameter of 100 mm and a thickness of 50 mm must be removed from the structure or cast and transported to the lab in saturated condition.

The outermost 20 mm should be cut off and the next 50 ± 2 mm thick slice should be cut as the test specimen. The end surface that was nearer to the outermost layer is the one to be exposed to the catholyte solution.

Place the test specimens in a vacuum chamber with both ends exposed.

Reduce the absolute pressure to 10-15 mbar within a few minutes and maintain this for three hours.

While the vacuum pump is still running fill the container with saturated Ca(OH)2 solution and maintain the vacuum for another hour before allowing air to re-enter the container.

Keep the specimens in solution for 18 ± 2 hours before removing, wiping them dry and fitting the rubber sleeves to the end of the sample.

Bolt the sample between the anolyte and catholyte reservoirs then fill with water to check for leaks.

Fill the anolyte container with NaOH and the catholyte container with NaCl, connect the electrodes to the power supply with the voltage preset at 30 V.

Record initial current and temperature, adjust the voltage if necessary, and select an appropriate test duration based on initial current.

After the test duration, disassemble the setup, rinse the specimen, wipe off excess water.

Split the specimen axially and spray 0.1 M silver nitrate solution on the freshly split section.

Once the white silver chloride precipitation is visible measure the penetration depth and calculate and average as per Figure 6.

What equipment and expertise are required for Non-Steady State Chloride migration coefficient testing?

Non-Steady State Chloride migration coefficient testing requires a large of amount of specialised equipment such as

A water-cooled diamond blade concrete saw.

A vacuum container capable of containing at least three specimens and a pump capable of maintaining a pressure of less than 50 mbar (5 kPa) in the container.

Silicone rubber sleeves to seal the edges of the test specimens.

Catholyte and anolyte reservoirs.

Stainless steel Anode and Cathode plates.

A Power supply capable of supplying 0 ∼ 60 V DC regulated voltage with an accuracy of ±0.1 V.

An ammeter capable of displaying current to ±1 mA.

Electrodes and wiring.

A thermometer or thermocouple with readout device capable of reading to ±1 °C.

Any suitable device for splitting the specimen.

A spray bottle to apply silver nitrate solution.

A slide calliper with a precision of ±0.1 mm.

A ruler with a minimum scale of 1 mm.

Distilled or de-ionised water.

Calcium hydroxide: Ca(OH)2, technical quality.

Sodium chloride: NaCl, chemical quality.

Sodium hydroxide: NaOH, chemical quality.

Silver nitrate: AgNO3, chemical quality.

Conducting this test requires expertise in electrical engineering for safe handling of the power supply and electrodes, proficiency in laboratory protocols to manage chemical use and specimen preparation, and knowledge of health and safety standards to ensure secure handling of hazardous materials. Additionally, access to a specialized lab equipped for precise cutting, vacuum sealing, and chemical analysis is essential for accurate setup and analysis of the test specimens.

What are the advantages of Non-Steady State Chloride migration coefficient testing?

The non-steady state chloride migration test provides a greater accuracy and reliability in measurement of the chloride penetration resistance of concrete compared to steady-state methods, due to its dynamic approach to simulating real-world conditions.

This test is faster than traditional chloride penetration tests reducing the time from weeks to a matter of hours or days.

The test yields quantitative data on the chloride migration coefficient, enabling precise comparisons between different concrete mixes or treatments.

Results can help predict the long-term durability and performance of concrete structures in chloride-laden environments, aiding in the design and maintenance planning.

Running cost of the test can be low if conductivity sensor method is used for determining the rate of chloride ingress.

What are the disadvantages of Non-Steady State Chloride migration coefficient testing?

Laboratory based test set-up hence there is a need to remove cores from concrete sample for testing.

Test set-up is sophisticated and needs expert handling.

Specialized knowledge and equipment is required, which might not be readily available in all testing facilities.

Despite the test itself being quicker, the preparation of specimens, including curing, slicing, and conditioning, is time-consuming.

The need for specialized equipment, chemicals, and trained personnel increases the overall cost of testing compared to simpler methods.

How accurate is Non-Steady State Chloride migration coefficient testing?

What are the limitations of Non-Steady State Chloride migration coefficient testing?

The non-steady state chloride migration test, while offering precise insights into concrete's chloride resistance, faces certain limitations impacting its practical application.

One significant concern is the representativeness of the test specimens; cores extracted for laboratory analysis may not accurately reflect the overall quality or variability of concrete in an actual structure, potentially leading to skewed results.

Additionally, the translation of lab-scale findings to real-world scenarios is not always straightforward due to environmental and structural differences that can affect concrete durability. Health and safety protocols also demand strict adherence, given the hazardous chemicals involved in the testing process.

Moreover, the method primarily assesses chloride ion movement in a single direction, potentially oversimplifying the complex, multidirectional ion transport phenomena occurring in field-exposed concrete elements.

Ancillary information

Maturity of test: > 10 years

Qualification & interpretation : Specialised lab

Service disruption: No

Preliminary works: Yes

Time consumption High (> one day)

Cost Low

Access to element 2 faces