What is Permeability coefficient testing?

Permeability coefficient testing of concrete is a laboratory based, destructive test technique used to assess a concretes ability to resist penetration of any substance, be it a liquid, gas, or chloride ion.

How does Permeability coefficient testing work?

The test works by exposing cylindrical concrete samples to a constant pressure of gas with THE permeability coefficient determined from the measure of the flow in a steady state.

Several permeability coefficients are measured for several pressures and the intrinsic permeability is calculated with the Klinkenberg approach. The gas used is nitrogen, oxygen or air.

This type of testing is most valuable for its ability to reveal the concrete's resistance to penetration of any substance particularly those which result in environmental degradation processes, such as carbonation, chloride attack, corrosion and freeze-thaw cycles.

What is Permeability coefficient testing used for?

Deterioration process | Defects | Control of repairs |

Complementary technique which can be |

How do I carry out Permeability coefficient testing?

The most common apparatus used for permeability coefficient testing of concrete uses a CEMBUREAU apparatus. The process involves several key steps:

A coring schedule must be developed based on the test objectives a completed based on correct sampling procedures. This could be a systematic random sampling of an entire structure or a targeted investigation of specific areas at risk of carbonation and corrosion.

Cut a 50mm cylindrical sample from the centre of the 150mm diameter core.

Pre-dry specimens to reach an average moisture concentration in equilibrium with 75 ± 2% relative humidity (RH) at 20 ± 1°C.

Measure the total evaporable water content by oven drying specimens at 105°C until weight loss is less than 0.5 g over 24 hours.

Calculate the evaporable moisture concentration from the total evaporable water content and the dry mass of the specimen.

Condition the specimens in a climate-controlled chamber or glove box with 75 ± 2% RH at 20 ± 1°C until moisture equilibrium is achieved.

Install the concrete specimen in the CEMBUREAU apparatus, designed to seal the specimen tightly and allow for gas to be applied to one side while measuring the flow or pressure drop on the other side.

Ensure all connections are airtight to prevent external air from influencing the test results.

Introduce a specific gas (e.g., carbon dioxide, nitrogen) at three different pressure stages, starting from 0.15 MPa and increasing incrementally, while ensuring the system is sealed and no external air influences the results. The pressure and type of gas will depend on the study's objectives.

Measure the flow rate of gas passing through the specimen or the pressure drop across the specimen over time. This can be achieved through flow meters or pressure sensors connected to the apparatus.

Accurately record the gas volume or pressure change to calculate the gas permeability coefficient.

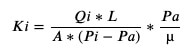

Calculate the gas permeability coefficient of the concrete based on the measured flow rate or pressure drop, considering the specimen's dimensions and the applied pressure gradient using Equation 1.

Assess the concrete's quality and suitability for specific applications based on the permeability to gases, comparing against relevant criteria or benchmarks.

What equipment and expertise are required for Permeability coefficient testing?

Carrying out permeability coefficient testing of concrete using the CEMBUREAU apparatus requires a combination of specialized equipment and technical expertise.

Specialised equipment required includes:

A CEMBUREAU permeameter designed to measure gas permeability of concrete disks.

A controlled environment for conducting tests at a stable temperature (20°C ± 2°C).

A gas supply system with pressure regulation (ranging from 0.1 to 0.6 MPa) and precision control (± 0.01 MPa).

Calibrated soap bubble flow meters (e.g., 150 ml, 15 ml, 5 ml, 1 ml) to measure the flow rate of gas passing through the specimen.

A Chronometer sensitive to 0.1 seconds, for precise timing of flow rate measurements.

Oxygen or Nitrogen gas supply.

Vernier callipers with 0.1 mm accuracy.

A climate-controlled chamber or glove box for preconditioning the concrete specimens at required humidity and temperature conditions.

An oven capable of reaching 105°C for drying specimens to measure the total evaporable water content.

Required expertise in permeability coefficient testing using the CEMBUREAU apparatus combines deep understanding of concrete science with skilled operation of specialized lab equipment.

Professionals must be proficient in handling and analysing data from tests, operating gas supply systems, and ensuring accurate measurements. Critical analytical skills are required for interpreting durability and performance results from calculated gas permeability coefficients. Safety awareness is also crucial, given the use of gases and laboratory equipment.

Attention to detail and rigorous adherence to testing protocols ensure the reliability and validity of the testing outcomes, underscoring the need for experienced personnel in executing these complex assessments.

What are the advantages of Permeability coefficient testing?

Provides accurate and precise measurements of gas permeability, crucial for assessing concrete durability.

Follows a standardized method, allowing for comparability of results across different studies and applications.

Helps predict the long-term performance of concrete structures by providing knowledge of the concrete’s resistance to deterioration.

Enables detailed evaluation of the effects of different mix designs, additives, and treatments on concrete's resistance and durability.

Low-cost test type.

What are the disadvantages of Permeability coefficient testing?

The testing setup and procedure are complex, requiring specialized equipment and trained personnel.

The need for specimen preconditioning means the testing process can be time-consuming.

Precise sample preparation is crucial; inconsistencies can affect test results.

The destructive nature of the test involves core extraction that can compromise structural integrity, is limited by accessible areas, and necessitates costly repairs, as such the number of samples that can be taken is limited.

How accurate is Permeability coefficient testing?

The accuracy and precision of permeability coefficient testing using the CEMBUREAU apparatus, like many specialized tests in materials science, depend on several factors including the strict adherence to testing protocols, the condition of the testing equipment, and the quality of the concrete specimens being tested.

This type of testing is generally considered to be accurate for assessing the permeability of concrete to gases, as it provides a direct measure of the gas flow through the material under controlled conditions. Exact test sensitivity and resolution are primarily a function of the test apparatus used.

The strong relationship between measured values for permeability and deterioration processes such as corrosion (Figure 6) and carbonation (Figure 7) highlights how successful this test is at accurately assessing concrete durability through measurement of a permeability coefficient

What are the limitations of Permeability coefficient testing?

Permeability coefficient testing, while highly informative, presents several limitations affecting its application and interpretation.

The destructive nature of gas permeability testing, involving core extraction, can affect structural integrity and faces limitations due to the need for stability and challenges in accessing critical areas. The limited number of cores that can be taken without impacting the structure restricts the thoroughness of the evaluation, making it difficult to accurately assess complex or large buildings.

Variability in results can be influenced by factors like moisture content, concrete mix, curing conditions, concrete age, and sample preparation, further complicating the accuracy of permeability measurements.

Additionally, fluctuations in laboratory temperature and humidity during the test, as well as operational precision in conducting the test, can lead to inconsistencies in results. The aftermath of testing involves necessary repair or restoration work at the extraction sites, introducing additional time and costs to the project. These post-testing requirements, can significantly impact project timelines and budgets, especially for large-scale structures or those in sensitive operational conditions.

Ancillary information

Maturity of test: > 10 years

Qualification & interpretation : Specialised lab

Service disruption: No

Preliminary works: Yes

Time consumption Medium ( one day)

Cost Low

Access to element 2 faces

References and further information